Steel Trench Shields

PRO SERIES SHIELDS

STEEL TRENCH SHIELDS | TRENCH BOXES

PRO SERIES™ SHIELDS

The Pro Series™ line of trench shields (trench boxes) from Pro-Tec Equipment incorporates performance and safety features that provide increased job safety and productivity. Pro Series trench shields (trench boxes) are available in 4″, 6″ and 8″ thick sidewalls. Each is designed to meet the depth and machine capacity for the intended project. The Pro HD Series offers the same standard and optional features as the Pro Series, but delivers exceptional depth ratings for extreme projects. They are available in 6″ and 8″ thick sidewalls. Learn more below.

How to Size a Steel Trench Shield

How to size a trench shield

To determine the right size of trench shield for your job, there are a series of questions you have to answer. Here are the main ones. Answer them, consult the tables and information which accompany our specific products, and always refer to manufacturer’s serialized specific tabulated data* and all applicable safety standards prior to each use.

What kind of job is it?

E.g., sewer, repair, water main, manhole, pump station, bore pit, etc.

Depth of cut?

Soil conditions?

B-soils (45 lbs per foot of pressure)

C-60 soils (60 lbs per foot of pressure)

C-80 soils (80 lbs per foot of pressure)

Hydrostatic

Figuring out spreader length

If working with pipe, what is the outside diameter of the pipe? (It is recommended that the trench shield be at least 12” wider than the pipe)

What is the width of the bucket, including any side cutters? (It is recommended that the trench shield be at least 12” wider than the bucket)

Figuring out Trench Shield length

If working with pipe, what is the length of the pipe sections? (It is recommended that the trench shield be 2’ – 4’ longer than the pipe)

Figuring out maximum weight of trench shield system

Take the working weight of the machine that is going to be used at the job site and divide it by 5. That will give you the maximum weight your machine can handle for a trench shield (including spreaders).

Example:

Cat 336E L has an operating weight of 86,200 lbs. 86200/5 = 17240. A trench shield with

spreader pipe would need to weigh less than 17,240 pounds to be used with this excavator.

Trench Shield Standards & Options

Pro-Tec Equipment

Trench Shield Standards

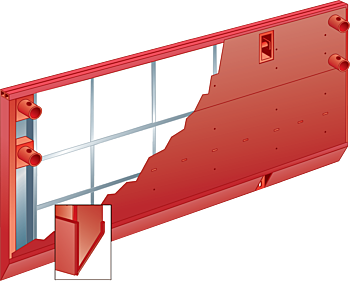

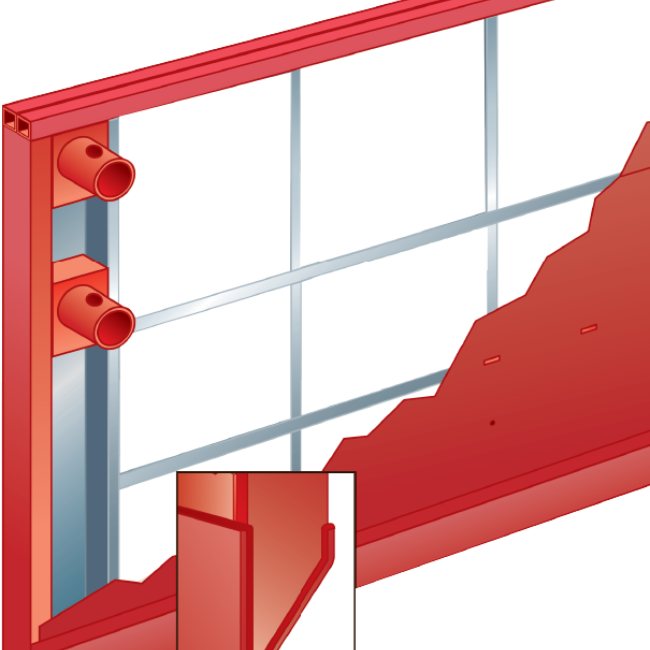

Pro-Tec Equipment trench shields (trench boxes) incorporate standard performance features that help improve productivity while increasing safety on the job.

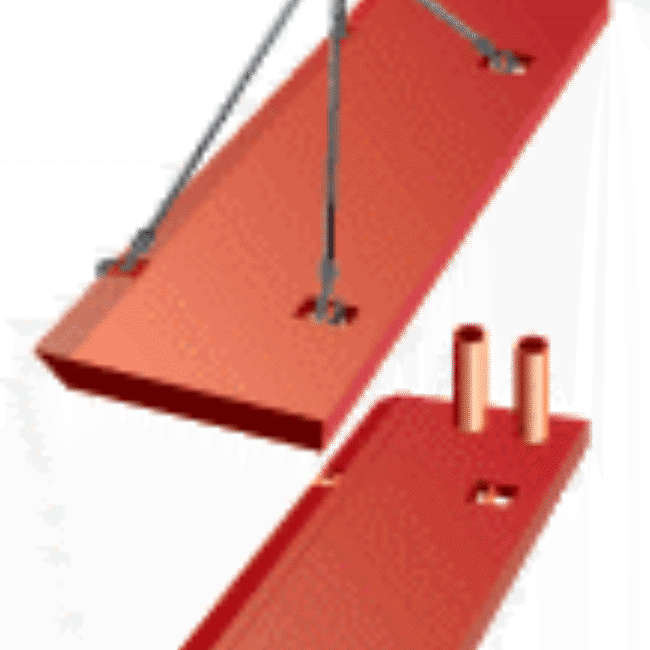

- Industry’s first standard 4-point lifting system

- Industry’s strongest knife edge

- Full length double top rail provides built-in “I” beam strength – on all 4” or thicker trench shields

- Recessed collar assemblies

- Professionally engineered and certified

Options:

What you need when you need it

The Pro-Plus package is available on all Pro-Series trench shields (trench boxes). The Pro-Plus option features three keys upgrades: double outside end post, ¾” thick collars and ½” x full length push pads. The Pro-Plus option is ideal for rental fleets because it can add usable years to the life of a trench shield.

Pro-Plus Package:

- Double outside end posts: Provide extra protection on the front and back end of the trench shield from excavator bucket damage

- ¾” thick collars: Reduces pin hole deformation and enlargement

- ½” x full length push pads: Attached to the top of the trench shield, the push pad provides an extra layer of protection from excavator bucket damage

Additional Options:

- Foam filling: Excessive weight buildup from soil and water inside of side walls is prevented by foam filling.

- Extended collars: The extended collars provide increased usability from standard spreader pipes and are available on all Pro and Pal series trench shields. Extended collars allow the width of trench shield system to be extended in 6” increments, while using the same size spreader pipe.

- Stacking pockets: Pro-Tec Equipment’s trench shields can be equipped with stacking pockets to connect shields vertically, while restricting lateral movement. With Pro-Tec Equipment’s stack pocket locations, all sizes of Pro-Tec Equipment Pro and Pal trench shields may be stacked with each other.

- Cutouts/replaceable doors: Not every project is the same. Some projects require pipe to go through the trench shield. Pro-Tec Equipment can handle that problem by incorporating cutouts into the trench shield. Replaceable doors are also available.

Railing Post System

Pro-Tec Equipment’s Railing Post System serves as an extra

precautionary measure, providing temporary railing around excavations that involve

trench shoring and trench shielding equipment.

Certified by a Registered

Professional Engineer to meet or exceed O.S.H.A. handrail standards, the Railing Post

Systems are two-piece, lightweight systems that can be adapted to work with sheetpile,

aluminum and steel trench shields and our Slide Rail Shoring panels.

Railing Post System features:

- Two-piece system: Post and Saddle are pinned together, enabling the posts to be easily removed to provide digging access for excavators.

- Universal saddles: One saddle to fit sheetpile, aluminum trench shields, steel trench shields and slide rail shoring panels

- Lightweight system: Constructed of tube steel. Designed to enable two workers to carry and place assembled systems on site.

- Registered by a Professional Engineer: meets O.S.H.A. handrail standards. Each system has a stamped technical data sheet.

Pro 4 Series – Steel Trench Shields

Industry-leading 4″ Steel Trench Shields | Trench

Boxes

Pro 4 Series

Pro Series Options:

- Foam filling – prevents soil and water buildup

- Extended collars

- Pro-Plus Package – adds life and usability

- Cutouts and replaceable doors

- Stacking pockets

- Custom sizes

Standard features:

- Industry’s first standard 4-point lift system

- Full-length double top rail provides built-in “I” beam strength

- Recessed collar assemblies

- Professional Engineer Certified to meet or exceed O.S.H.A. requirements

- On knife edge shields: the industry’s strongest knife edge

- On flat bottom shields: full-length double bottom rail provides built-in “I” beam strength bucket damage

| Height x Length | Model | Weight** | Pipe Clearance | Shield Capacity* | Depth of Cut* B-Soils | Depth of Cut* C-60 Soils | Depth of Cut* C-80 Soils |

|---|---|---|---|---|---|---|---|

| ft | lbs | in | psf | ft | ft | ft | |

| 4 x 10 | Pro 4-410 | 2920 | 21 | 3000 | 67 | 50 | 38 |

| 4 x 12 | Pro 4-412 | 3290 | 21 | 2640 | 58 | 44 | 33 |

| 4 x 16 | Pro 4-416 | 4100 | 21 | 1440 | 31 | 24 | 19 |

| 4 x 20 | Pro 4-420 | 4880 | 21 | 960 | 20 | 16 | 12 |

| 4 x 24 | Pro 4-424 | 5700 | 21 | 660 | 14 | 11 | 9 |

| 6 x 10 | Pro 4-610 | 3750 | 41 | 3000 | 67 | 50 | 38 |

| 6 x 12 | Pro 4-612 | 4340 | 41 | 3000 | 67 | 50 | 38 |

| 6 x 16 | Pro 4-616 | 5440 | 41 | 1500 | 32 | 25 | 20 |

| 6 x 20 | Pro 4-620 | 6600 | 41 | 1140 | 24 | 19 | 15 |

| 6 x 24 | Pro 4-624 | 7800 | 41 | 780 | 16 | 13 | 10 |

| 8 x 10 | Pro 4-810 | 4650 | 55 | 2400 | 52 | 40 | 31 |

| 8 x 12 | Pro 4-812 | 5390 | 55 | 2040 | 44 | 34 | 27 |

| 8 x 16 | Pro 4-816 | 6800 | 55 | 1500 | 32 | 25 | 20 |

| 8 x 20 | Pro 4-820 | 8240 | 55 | 1140 | 24 | 19 | 15 |

| 8 x 24 | Pro 4-824 | 9850 | 55 | 780 | 16 | 13 | 11 |

| 10 x 10 | Pro 4-1010 | 5750 | 70 | 1740 | 37 | 29 | 23 |

| 10 x 12 | Pro 4-1012 | 6640 | 70 | 1440 | 30 | 24 | 19 |

| 10 x 16 | Pro 4-1016 | 8320 | 70 | 1140 | 24 | 19 | 16 |

| 10 x 20 | Pro 4-1020 | 9990 | 70 | 960 | 20 | 16 | 13 |

| 10 x 24 | Pro 4-1024 | 11820 | 70 | 780 | 16 | 13 | 11 |

*PSF (pounds per square foot) ratings indicate maximum shield capacities. Depths are based on B, C and C-80 soil types as described in OSHA’s 29 CFR Part 1926 Subpart P, October 31, 1989 with Type B not exceeding 45 PSF per foot of depth, Type C not exceeding 60 PSF per foot of depth and Type C-80 not exceeding 80 PSF per foot of depth. Determine actual soil pressure and consult manufacturers’ tabulated data prior to each use.

** Weight of shields = two sidewalls, no

spreaders.

Job

site photos are strictly

intended for general product information only and may not comply with all applicable

safety standards. Always refer to manufacturers’ serialized specific tabulated data,

O.S.H.A. 29 CFR 1926 Subpart P for excavations and all applicable safety standards prior

to each use

Pro 6 Series – Steel Trench Shields

Pro Series Options:

Pro Series Options:

- Foam filling – prevents soil and water buildup

- Extended collars

- Pro-Plus Package – adds life and usability

- Cutouts and replaceable doors

- Stacking pockets

- Custom sizes

Standard features:

- Industry’s first standard 4-point lift system

- Full-length double top rail provides built-in

- “I” beam strength

- Recessed collar assemblies

- Professional Engineer Certified to meet or exceed O.S.H.A. requirements

- On knife edge shields: the industry’s strongest knife edge

- On flat bottom shields: full-length double bottom rail provides built-in “I” beam strength bucket damage

| Heightx Length | Model | Weight** | Pipe Clearance | ShieldCapacity* | Depth of Cut* B-Soils | Depth of Cut* C-60 Soils | Depth of Cut* C-80 Soils |

|---|---|---|---|---|---|---|---|

| ft | lbs | in | psf | ft | ft | ft | |

| 4 x 20 | PRO 6-420 | 5490 | 21 | 1380 | 31 | 23 | 18 |

| 4 x 24 | PRO 6-424 | 6440 | 21 | 1020 | 21 | 17 | 13 |

| 4 x 28 | PRO 6-428 | 7320 | 21 | 720 | 16 | 12 | 10 |

| 6 x 20 | PRO 6-620 | 7410 | 41 | 1500 | 32 | 25 | 20 |

| 6 x 24 | PRO 6-624 | 8850 | 41 | 1080 | 23 | 18 | 14 |

| 6 x 26 | PRO 6-626 | 9430 | 41 | 900 | 19 | 15 | 12 |

| 6 x 28 | PRO 6-628 | 10250 | 41 | 780 | 16 | 13 | 11 |

| 8 x 16 | PRO 6-816 | 7740 | 64 | 1860 | 40 | 31 | 24 |

| 8 x 20 | PRO 6-820 | 9290 | 64 | 1500 | 32 | 25 | 20 |

| 8 x 24 | PRO 6-824 | 11100 | 64 | 1080 | 23 | 18 | 15 |

| 8 x 26 | PRO 6-826 | 11800 | 64 | 900 | 19 | 15 | 12 |

| 8 x 28 | PRO 6-828 | 12660 | 64 | 780 | 16 | 13 | 11 |

| 10 x 16 | PRO 6-1016 | 9900 | 85 | 1440 | 30 | 24 | 19 |

| 10 x 20 | PRO 6-1020 | 12000 | 85 | 1200 | 25 | 20 | 16 |

| 10 x 24 | PRO 6-1024 | 13920 | 85 | 1080 | 22 | 18 | 15 |

| 10 x 26 | PRO 6-1026 | 14350 | 85 | 900 | 18 | 15 | 13 |

| 10 x 28 | PRO 6-1028 | 15200 | 85 | 780 | 16 | 13 | 11 |

*PSF (pounds per square foot) ratings indicate maximum shield capacities. Depths are based on B, C and C-80 soil types as described in OSHA’s 29 CFR Part 1926 Subpart P, October 31, 1989 with Type B not exceeding 45 PSF per foot of depth, Type C not exceeding 60 PSF per foot of depth and Type C-80 not exceeding 80 PSF per foot of depth. Determine actual soil pressure and consult manufacturers’ tabulated data prior to each use.

** Weight of shields = two sidewalls, no spreaders.

Job site photos are strictly intended for general product information only and may not comply with all applicable safety standards. Always refer to manufacturers’ serialized specific tabulated data, O.S.H.A. 29 CFR 1926 Subpart P for excavations and all applicable safety standards prior to each use

Pro 8 Series – Steel Trench Shields

Pro 8 Series 8” Double Wall Shields

Pro Series Options:

- Foam filling – prevents soil and water buildup

- Extended collars

- Pro-Plus Package – adds life and usability

- Cutouts and replaceable doors

- Stacking pockets

- Custom sizes

Standard features:

- Industry’s first standard 4-point lift system

- Full-length double top rail provides built-in “I” beam strength

- Recessed collar assemblies

- Professional Engineer Certified to meet or exceed O.S.H.A. requirements

- On knife edge shields: the industry’s strongest knife edge

- On flat bottom shields: full-length double bottom rail provides built-in “I” beam strength bucket damage

| Heightx Length | Model | Weight** | Pipe Clearance | ShieldCapacity* | Depth of Cut* B-Soils | Depth of Cut* C-60 Soils | Depth of Cut* C-80 Soils |

|---|---|---|---|---|---|---|---|

| ft | lbs | in | psf | ft | ft | ft | |

| 4 x 20 | PRO 8-420 | 6250 | 21 | 2117 | 47 | 35 | 26 |

| 4 x 24 | PRO 8-424 | 7280 | 21 | 1426 | 32 | 24 | 18 |

| 4 x 28 | PRO 8-428 | 8250 | 21 | 1034 | 23 | 17 | 13 |

| 4 x 30 | PRO 8-430 | 8770 | 21 | 899 | 20 | 15 | 11 |

| 6 x 20 | PRO 8-620 | 8350 | 41 | 2000 | 44 | 33 | 25 |

| 6 x 24 | PRO 8-624 | 9790 | 41 | 1461 | 32 | 24 | 18 |

| 6 x 28 | PRO 8-628 | 11150 | 41 | 1055 | 23 | 18 | 13 |

| 6 x 30 | PRO 8-630 | 11990 | 41 | 915 | 20 | 15 | 11 |

| 8 x 20 | PRO 8-820 | 10470 | 64 | 1800 | 40 | 30 | 23 |

| 8 x 24 | PRO 8-824 | 12340 | 64 | 1463 | 33 | 24 | 18 |

| 8 x 28 | PRO 8-828 | 14070 | 64 | 1200 | 25 | 20 | 16 |

| 8 x 30 | PRO 8-830 | 15000 | 64 | 916 | 20 | 15 | 11 |

| 10 x 20 | PRO 8-1020 | 12900 | 85 | 1740 | 37 | 29 | 23 |

| 10 x 24 | PRO 8-1024 | 15100 | 85 | 1260 | 26 | 21 | 17 |

| 10 x 26 | PRO 8-1026 | 15990 | 85 | 1140 | 25 | 19 | 14 |

| 10 x 28 | PRO 8-1028 | 17100 | 85 | 1020 | 23 | 17 | 13 |

| 10 x 30 | PRO 8-1030 | 18200 | 85 | 900 | 20 | 15 | 11 |

Pro HD Series – Heavy Duty Sheilds

| Height x Length | Model | Weight** | Pipe Clearance | Shield Capacity* | Depth of Cut* B-Soils | Depth of Cut* C-60 Soils | Depth of Cut* C-80 Soils |

|---|---|---|---|---|---|---|---|

| ft | lbs | in | psf | ft | ft | ft | |

| 8 x 24 | PRO HD6-824 | 13100 | 64 | 1500 | 33 | 25 | 19 |

| 10 x 16 | PRO HD6-1016 | 11200 | 85 | 1551 | 34 | 26 | 19 |

| 10 x 20 | PRO HD6-1020 | 14150 | 85 | 1500 | 33 | 25 | 19 |

| 10 x 24 | PRO HD6-1024 | 18010 | 85 | 1481 | 33 | 25 | 19 |

| Height x Length | Model | Weight** | Pipe Clearance | Shield Capacity* | Depth of Cut* B-Soils | Depth of Cut* C-60 Soils | Depth of Cut* C-80 Soils |

|---|---|---|---|---|---|---|---|

| ft | lbs | in | psf | ft | ft | ft | |

| 8 x 24 | PRO HD8-824 | 15870 | 64 | 1902 | 42 | 32 | 24 |

| 8 x 28 | PRO HD8-828 | 23130 | 64 | 1800 | 40 | 30 | 23 |

| 10 x 24 | PRO HD8-1024 | 18470 | 85 | 1879 | 42 | 31 | 23 |

| 10 x 28 | PRO HD8-1028 | 26000 | 85 | 1440 | 32 | 24 | 18 |

Spreaders – Trench Box Spreader Sets 8″ Schedule 80 Spreader Pipe

4-Pipe and 5-Pipe Sets

There are several variations in the style of common trench boxes. Some are designed to utilize 4 spreader pipe (such as those set up in a 4-pipe repair, also known as 4-pipe independent) which provides maximum pipe clearance through out the trench shield, 4-pipe pull which provide lower front spreaders to allow excavator boom clearance) and others are designed to utilize 5 spreader pipe.

The most commonly used spreader pipe on Pro-Series trench shields are the 8″ schedule 80 spreader pipe. No matter if the trench box is set up to accept 4-pipe or 5-pipe, it is stated on our engineer stamped certification sheets that a minimum of 2 spreader pipes are required on each end with the approved pins and keepers. In general, the 5th spreader is used as a means to rigidity to larger, deeper trench boxes.

For specially designed trench shields that require 5 or more spreader pipe, or pipe of a different specification (i.e. 10″ sch. 120), please refer to certification sheet.

| Model | Inside Width | Weight |

|---|---|---|

| in | lbs | |

| H4-24 | 24 | 470 |

| H4-30 | 30 | 560 |

| H4-36 | 36 | 650 |

| H4-42 | 42 | 740 |

| H4-48 | 48 | 820 |

| H4-60 | 60 | 1010 |

| H4-72 | 72 | 1170 |

| H4-84 | 84 | 1350 |

| H4-96 | 96 | 1510 |

| H4-108 | 108 | 1692 |

| H4-120 | 120 | 1860 |

| H4-132 | 132 | 2040 |

| H4-144 | 144 | 2210 |

| Model | Inside Width | Weight |

|---|---|---|

| in | lbs | |

| H5-24 | 24 | 590 |

| H5-30 | 30 | 690 |

| H5-36 | 36 | 800 |

| H5-42 | 42 | 910 |

| H5-48 | 48 | 1020 |

| H5-60 | 60 | 1240 |

| H5-72 | 72 | 1450 |

| H5-84 | 84 | 1670 |

| H5-96 | 96 | 1890 |

| H5-108 | 108 | 2110 |

| H5-120 | 120 | 2320 |

| H5-132 | 132 | 2540 |

| H5-144 | 144 | 2760 |

FEATURES AND BENEFITS

PROTECTION ENGINEERED FOR ADDED SAFETY

Full length double tube top rail provides built in "I" beam strength, helps prevent bucket damage. Superior structural strength provides greater durability and depth ratings. Additional 4 Point System horizontal and vertical structural members in the sidewall impart maximum shield strength and better depth ratings than competitive shields. High strength steel, Schedule 80 steel pipe spreaders and superior welding techniques complete the package. Collars are encased in heavy wall tubing inserted between twin end-posts. Collars are 100% perimeter welded to impart maximum durability to these critical connecting points.

INDUSTRY’S FIRST, SAFER 4-POINT LIFTING SYSTEM

Industry's first 4-point lifting system makes handling and assembly easier, faster and safer.

Contact Pro-Tec

Why Pro-Tec Equipment

Pro-Tec Equipment is designed with superior quality, safety, dependability and durability in mind. We have continued to expand our range of equipment and services to ensure you, our customer, have what you need to meet the constant challenges you face at the worksite. Your success is our success.

Learn More*PSF (pounds per square foot) ratings indicate maximum shield capacities. Depths are based on B, C and C-80 soil types as described in OSHA's 29 CFR Part 1926 Subpart P, October 31, 1989 with Type B not exceeding 45 PSF per foot of depth, Type C not exceeding 60 PSF per foot of depth and Type C-80 not exceeding 80 PSF per foot of depth. Determine actual soil pressure and consult manufacturers Tabulated Data prior to each use.

Job site photos are strictly intended for general product information only and may not comply with all applicable safety standards. Always refer to manufacturers’ serialized specific tabulated data, O.S.H.A. 29 CFR 1926 Subpart P for excavations and all applicable safety standards prior to each use.